Products

Cutlam 1.1

A bench-mounted cutting machine for a wide range of applications. Robust and easy to use,with a deported motor design, this machine has a very large cutting capacity.

A bench-mounted cutting machine for a wide range of applications. Robust and easy to use,with a deported motor design, this machine has a very large cutting capacity.This machine offers a spacious cutting table, made of treated anti corrosive cast iron. It is also easy to handle with a fully opening cover and remote motor. The 4 perpendicular grooves enable you to clamp components of thicknesses up to 120 mm. The CUTLAM®1.1 can be equipped with Ø 250 to 305 mm cut-off wheels.

Fitted with a speed adjuster and a powerful 3.8 Kw motor particularly adapted to Ø 305 mm wheels, the CUTLAM®1.1 is perfect for intensive use.

The high-capacity recirculation system with pre-filter and decanter compartments ensures optimum lubrication and cooling by a multi-point spray.

The Cutlam 1.1 is a bench-mounted cutting machine designed for a wide range of applications. Robust and easy to use, this machine has a very large cutting capacity.

- Spacious cutting table made from anti-corrosive cast iron

- Easy-to-handle fully opening cover and remote motor

- Ability to clamp components of thicknesses up to 120mm

- Can be equipped with Ø 250 to 305mm cut-off wheels

- Speed adjuster and powerful 3.8 kW motor – perfect for intensive use

- High-capacity recirculation system with pre-filter and decanter compartments, ensuring optimum lubrication and cooling by a multi-point spray

- External shower head combined with a tilted cutting chamber for easy cleaning

- Inlet filter ensuring samples do not fall down the large-diameter outlet pipe

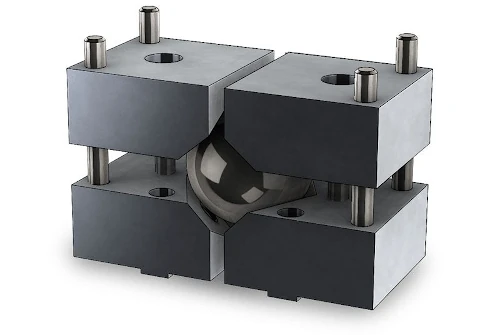

Cutting of a sphere

One of the recurrent issues remaining in the cutting processes is the clamping of spherical parts. The implementation of this kind of vice on the cutlam®1.1 enables to cut spheres having a diameter going from 30 mm to 60 mm

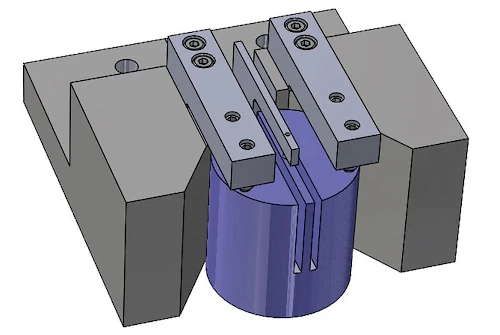

Cutting of a glass cylinder with double wheel

Tools for removing a 3 mm slice from a Ø 50 mm glass cylinder, height 50 mm. This article includes the supply and installation of a specific clamping and a double wheel on a CUTLAM® 1.1 machine..

An external shower head combined with a tilted cutting chamber base makes cleaning easy, and an inlet filter ensures that your samples do not fall down the large-diameter outlet pipe.

This machine is offering 2 lateral openings, giving the possibility of cutting bars which have a 60 mm diameter.

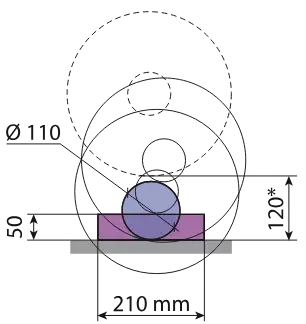

Theoretical cutting capacity: Ø 305 mm

*space under wheel

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| B6301 | Cutlam Micro 1.1 – Laboratory micro cutting machine 75-150mm dia | Each | p.o.r. |

Accessories

Description

Solid painted-steel piece of furniture specially designed for CUTLAM products.

It contains a storage door for tools and cut-off wheels, a drawer on top and a space for the recirculation tank.

This piece of furniture is stable and has adjustable feet.

For machine CUTLAM1.1

Dimensions L x H x P : 630 x 800 x 835 mm mm 60 M0100 00

For machine CUTLAM3.1

Dimensions L x H x P : 700 x 800 x 1050 mm

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 60 MO100 00 | CUTLAM support cabinet for Cutlam 1.1 | Each | p.o.r. | ||

| 60 M0310 00 | Support cabinet for CUTLAM 3.1 | Each | p.o.r. |

Description

The LAM PLAN vaccuming system extracts the “polluted” air inside the cutting chamber of your cutting machine.

- A special multilayer filter will stop the smallest polluting particles, thus preventing their dispersion into the atmosphere.

- The cutting fluid, in the liquid state, is returned to the cutting machine recirculation tank to be reused. (An evacuation is provided for this purpose on the vacuuming system).

- A cartridge post-filter, located above the suction system, ensures a high filtration level, up to 99.97%.

- An adapter part (LAM PLAN code 60CT20820) is provided to adapt the suction hose to the canopy of the LAM PLAN cutting machine.

- The vacuuming system is mounted on a trolley with wheels, allowing an easy positioning.

- A drain valve, located in the trolley, collects the condensate.

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 60 CT204 00 | Oil mist extraction device – A1 | Each | p.o.r. |

Description

Double vice with fast tightening system (left and right side of the wheel)

2 x 2 elements vice, without sole, to obtain maximal length clamping

Jaw width 80 mm

Jaw height 45 mm

T-slot 12 mm screw included

Lever ( left and right )

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 60 CT200 20 | Double vice with fast tightening system | Each | p.o.r. |

Description

Double vice with screw tightening system (left and right side of the wheel)

2 x 2 element vice, without sole to obtain maximal length clamping

Jaws width 80 mm, Jaws height 45 mm

T-slot 12 mm screw included

Left and right levers

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 60 CT200 40 | Double vice with screw tightening system | Each | p.o.r. |

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 60 081282 20 | Universal clamping KOPAL 61 | Each | p.o.r. |

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 60 081282 40 | Lift for KOPAL 61 | Each | p.o.r. |

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 60 00285 90 | Long cam for KOPAL 61 | Each | p.o.r. |

Description

Transversal table (X movement) to perform parallel cuts.

Manual movement with roller

stroke 100 mm

Display accuracy: 0,01 mm

Can receive the right vice reference 60 CT200 20 or 60 CT200 40.

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 60 CT205 20 | Transversal table (X movement) to perform parallel cuts | Each | p.o.r. |

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 60 CT206 20 | Double vice with fast tightening system for transversal table | Each | p.o.r. |