Products

Sputter Coater

The CCU-010 Series high compact vacuum coating system

Designed for the highest demands in the field of sample preparation

A smart modular device

The CCU-010 is a compact, fully automatic sputter coater and/or carbon coater that is very simple to use. Due to the unique plug-in concept the device is easily configurable for sputtering or vaporising by simply changing the process head.

Prior and / or after the coating a plasma treatment can be applied. The modular design makes it easy to avoid cross contamination between metal and carbon deposition.

The CCU-010 has a static specimen stage with height adjustment and tilt included. It can be fitted with an optional variable speed rotation stage or a rotary planetary stage, each with options for holding different specimen and stub types.

With all specimen stages film thickness monitoring is included as standard.

The modular concept makes it easy to convert the unit from a fine vacuum unit into a high-vacuum unit later on.

The thoroughly design relating to materials, surfaces and profiles results in extraordinarily short process times.

Two additional standard vacuum flanges allow connecting third party devices.

Easy start-up and servicing

Unpack, connect and start! The plug-and-play concept allows you to start up the device by yourself. You only need to connect the power supply and process gas.

With the integrated USB service interface, a service technician can run a quick error analysis on site or remotely via an Internet connection.

The modular set-up allows a straight-forward replacement of defective components.

- Automatic valve control for two process gases and venting.

- Speed-controlled rotary or planetary gear table as option, both for holding different specimen and stub types.

- Intuitive user software with many useful features.

- Easy creation of coating recipes, which guarantee reproducible results.

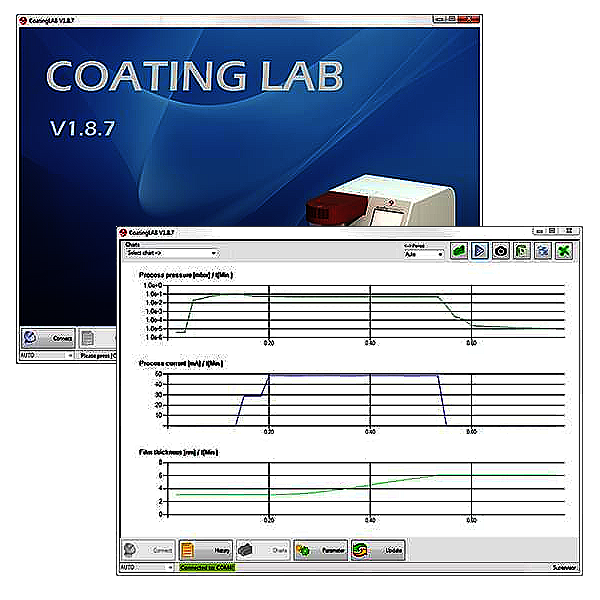

- Diagramed process data with Windowsbased software Coating LAB.

- You can keep the system under vacuum if it is switched-off or in case of power loss (if operated with oil-free pumps).

- Feature to vent the system automatically in case of power loss which prevents the systemfrom getting contaminated by backing pump oil (if operated with oil-sealed pump).

- Simple plug-in electrical and pneumatic interface for connecting the coating head to the base unit allows swapping between the modules within seconds.

- The process head recognition automatically turns the display to the desired menu.

- Technology-leading Swiss quality.

Clever vacuum design

The CCU-010 coating unit is available in two versions. While the CCU-010 LV fine vacuum base is designed for routine high quality sputtering and carbon coating for SEM and EDX, the CCU-010 HV high-vacuum system covers the highest-level SEM, TEM and thin film application.

The modular concept makes it easy to convert the unit from a fine vacuum unit into a high-vacuum unit later on. The thoroughly design relating to materials, surfaces and profiles results in extraordinarily short process times. Two additional standard vacuum flanges allow connecting third party devices.

Safematic CCU-010 coater family.

- High performance sputtering, carbon coating and plasma treatment

- Patented carbon spooling – up to 50 carbon coatings without user intervention

- Unique plug-and-go sputter and carbon coating modules

- Class–leading vacuum performance and fast pump down times

- Compact, reliable and easy to service

- Dual-position film thickness monitor to accommodate different specimen sizes

- Actively cooled sputter head ensures coating quality and allows long run-times

Metal Sputter Head

SP-010

Metal Sputter Head

SP-011

High Power

Carbon Thread Head

CT-010

Etching Unit

ET-010

Glow Discharge

GD-010

ET-010 Etching Unit

Allows to Apply Plasma to the Substrates

For specimen pre-treatment or after-treatment combined with a coating process the etching unit allows to apply plasma to the substrates. With this accessory one can select Argon, extra etching gas or environmental air either as process gas.

This allows cleaning of the samples prior to a coating and increasing the adhesion of thin films. Additionally it would be possible to modify the surface properties of a coated sample by a plasma treatment after the coating.

With air plasma it is possible to turn a thin carbon layer from hydrophobic to hydrophilic for example. The adjustable process pressure ranges from 2 E-1 mbar to 1 mbar with a selectable plasma current from 10 to 50 mA..

| Download Technical Note |

Description

Application Fine Vacuum

As base unit for our vacuum coating system the CCU-010 LV is designed for routine high quality sputter and/or carbon coatings for SEM and EDX. The modular concept allows for the subsequent conversion to a high vacuum coating system.

A Smart Device

A Sputter coater and/or carbon coater with options for plasma treatment within one device? Yes, this is possible with our table top vacuum coating system. By simply changing the process head, you can easily configure the unit for all these applications. Adjust the unit to your requirements or extend the functionality afterwards. A coating thickness monitor close to the sample is standard fitting which will precisely monitor and control film thickness of carbon and metal films.

Do Not Waste Time

The use of high-quality materials and components in combination with innovative ideas produces extraordinarily short process times. Create recipes via the modern user interface and use the automatic mode for reliable and reproducible production of thin coatings.

Low Consumption

The efficient gas control optimized for high vacuum reduces the consumption of your process gas. With a target diameter of 54 mm and high target utilization, you save money on consumables.

Compact and Practical

Save valuable laboratory space thanks to small dimensions. Weight has been minimized to reduce transport costs. Standardised small-flange quick connections ( ISO-KF ) act as interfaces with your connections.

Easy Start-up and Servicing

Unpack, connect, start! Do away with high start-up costs. The plug-and-play concept allows you to start up the device yourself. You only need to connect the power supply and the process gas. The service technician can run a quick error analysis thanks to the integrated USB service interface. The modular set-up allows for the targeted replacement of defective components.

Specifications

| Dimensions (L x W x H) | 570 x 360 x 350 mm |

| Weight | 22 kg |

| Glass cylinder | Ø 120 mm (DN 100 ISO-KF compatible) |

| Imposion guard | Plastic splinter shield around glass receptacle |

| Targets | Ø 54 mm and thickness up to 3 mm |

| Coating time | 0.5 … 990 s |

| Coating current | 10 … 100 mA |

| Final vacuum | < 5 · 10–3 mbar (with backing pump Pascal 2005 SD) |

| Vacuum measuring system | Pirani measuring probe (measuring range up to 1 E-3 mbar) |

| Display | 115 x 86 mm, TFT graphical display |

| Sample table | Ø 80 mm, holds numerous sample plates Height adjustment 0 … 50 mm Tilt 0 … 45° |

| Pump system | Ext. backing pump (option) |

| Connections, electrical | Device plug C14, 90-260 VAC, 47..63 Hz, 500 W |

| Connections, gas | Process gas: Ø 6 mm, venting gas : Ø 6 mm, plasma gas: Ø 6 mm |

| Connections, backing pump | Mechanical: Flange connection DN 25 ISO-KF Electrical: Connector socket C13, secured with 10 A therm. Circuit breaker. |

Features

- Reliable, solid basic unit

- Lightweight Aluminum base, small footprint

- Integrated vacuum measuring (Pirani, cold cathode vacuum gauge)

- Plasma treatment option (etching)

- Implosion guard with safety monitoring

- Wide range power supply (90-260 VAC)

- Process head standard interface (gas and electric)

- Automatic process head detection

- 5.7″ TFT touch display

- Recipes programmable which guarantee reproducible results

- History function with storage / view of the last processes

- Feature for automatic venting of system in the event of power loss. This prevents the system from becoming

- contaminated with backing pump oil.

- Intuitive user software with many practical features

- Graphical representation of process data with Windows-based coating LAB software (option)

- External alarm output

- USB service interface for easy analysis and software upgrades

- Various accessories, tools, cables and assembly material included in delivery

- Flange connection (DN 25 ISO-KF) for connecting an external backing pump (LV version)

- Power socket and cable to control the external roughing pump

- Automatic valve control for two process gases and venting

- 6 mm plug connections for two process gases and vent gas

- Can be used as a pure pumping unit

- Operating manual

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 100000 | CCU-010 LV (low vacuum) | Each | p.o.r. |

Description

Application high vacuum

The CCU-010 high vacuum sputter and carbon coater was designed for the highest demands in the field of sample preparation. Premium components and a smart design allow excellent results in ultra-high-resolutionapplications. Our device is a compact, fully automatic sputter coater and/or carbon coater. The CCU-010 HV base unit pumping system is totally oil-free and includes a high performance turbo pump and diaphragm backing pump, both internally located, giving the coater a very small footprint (no cumbersome rotary pump and vacuum lines). It is a mini sputter coater size wise with big potential. The use of an oil-free, pumping system reduces contamination or defects in the coating to a minimum. The device can be kept under vacuum when switched off. This efficiently protects the system from dust and humidity and creates a fast pumping speed and proper vacuum conditions for high-quality coatings.

A smart device

A sputter coater and/or carbon coater with options for plasma treatment within one device? Yes, this is possible with our table top coating system. By simply changing the process head, you can easily configure the unit for all these applications. Adjust the unit to your requirements or extend the functionality afterwards. A coating thickness monitor close to the sample is standard fitting which will precisely monitor and control film thickness of carbon and metal films.

Do not waste time

The use of high-quality materials and components in combination with innovative ideas produces extraordinarily short process times. Create recipes via the modern user interface and use the automatic mode for reliable and reproducible production of thin coatings.

Low consumption

The efficient gas control optimized for high vacuum reduces the consumption of your process gas. With a target diameter of 54 mm and high target utilization, you save money on consumables.

Compact and practical

Save valuable laboratory space thanks to small dimensions. Weight has been minimized to reduce transport costs. Standardised small-flange quick connections ( iso-kf ) interface with your existing connections.

Easy start-up and servicing

Unpack, connect, start! Do away with high start-up costs. The plug-and-play concept allows you to start up the device yourself. You only need to connect the power supply and the process gas. The service technician can run a quick error analysis thanks to the integrated usb service interface. The modular set-up allows for the targeted replacement of defective components.

Specifications

| Dimensions (L x W x H) | 570 x 360 x 350 mm |

| Weight | 29 kg |

| Glass cylinder | Ø 120 mm (DN 100 ISO-KF compatible) |

| Imposion guard | Plastic splinter shield around glass receptacle |

| Targets | Ø 54 mm and thickness up to 3 mm |

| Coating time | 0.5 … 990 s |

| Coating current | 10 … 100 mA (higher currents upon request) |

| Final vacuum | < 2 · 10–6 mbar |

| Vacuum measuring system | Pirani and cold cathode measuring system |

| Display | 115 x 86 mm, TFT graphical display |

| Sample table | Ø 80 mm, holds numerous sample plates Height adjustment 0 … 50 mm Tilt 0 … 45° |

| Double-quartz system | Piezoelectric crystal: Frequency 6 MHz, Ø 14 mm, thickness 0.4 mm Measuring frequency depends on coating thickness |

| Pump system | Integrated membrane and turbo pump |

| Connections, electrical | Device plug C14, 90-260 VAC, 47..63 Hz, 500 W |

| Connections, gas | Process gas: Ø 6mm, venting gas: Ø 6mm, plasma gas: Ø 6mm |

Features

- Reliable, solid basic unit

- Lightweight Aluminum base, small footprint

- Integrated diaphragm pump (MD 1 Vario-SP)

- Integrated turbo pump (Pfeiffer Hi Pace 80)

- Full range vacuum measuring (Pirani, cold cathode vacuum gauge)

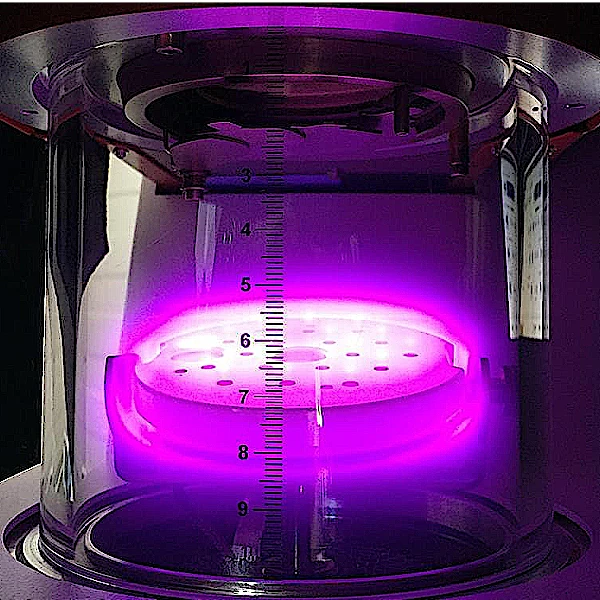

- Glass process chamber ∅ 105 mm (DN 100 ISO-KF compatible) with a scale indicating the working distance

- Specimen stage, height-adjustable and tiltable (∅ 80 mm) to hold your samples. The table can be easily removed without tools for cleaning purposes.

- Speed-controlled rotary or planetary gear table with different options for holding samples (option)

- Integrated film thickness monitor, usable in two positions (center / edge)

- Plasma treatment option (etching)

- Implosion guard with safety monitoring

- Wide range power supply (90-260 VAC)

- Process head standard interface (gas and electric)

- Automatic process head detection

- 5.7″ TFT touch display

- Sputtering of indium tin oxide (ITO) and carbon possible

- Recipes programmable which guarantee reproducible products

- History function with storage / view of the last processes

- Feature for automatic venting of system in the event of power loss. This prevents the system from becoming contaminated with backing pump oil.

- Intuitive user software with many practical features

- Graphical representation of process data with Windows-based coating LAB software (option)

- External alarm output

- USB service interface for easy analysis and software upgrades

- Various accessories, tools, cables and assembly material included in delivery

- Power socket and cable to control the external roughing pump

- Automatic valve control for two process gases and venting

- 6 mm plug connections for two process gases and vent gas

- Can be used as a pure pumping unit

- Operating manual

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 100001 | CCU-010 HV (high vacuum) | Each | p.o.r. |

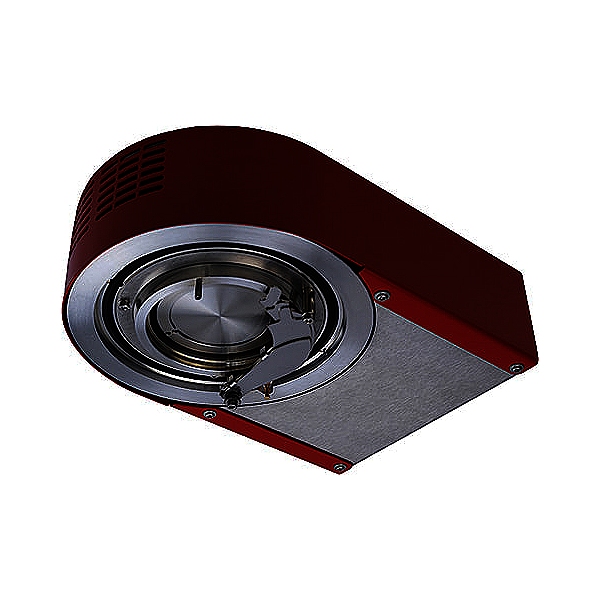

Description

An Intelligent Head

Adding the final touch! Safematic sets new standards in laboratory coating with its compact sputter head.

Our SP-010 sputtering system is designed for high quality sputter deposition.

See for yourself the smaller form factor and the numerous features that our engineers have packed into this head.

Such as efficient active cooling, which allows continuous coating times up to 50 minutes.

Our sputtering modules plug into our CCU-010 HV and CCU-010 LV coating systems and are immediately ready to go.

Specifications

| Dimensions (L x W x H) | 230 x 160 x 60 mm |

| Weight | 2.9 kg |

| Targets | Ø 54 mm and thickness up to 3 mm |

| Connections, electrical | DSUB |

| Connections, gas | DSUB |

| Temperature range | 10 … 40 °C |

Features

- The magnetron sputter head allows for fine-grained sputtering for high-resolution FE-SEM applications.

- Use of targets with a diameter of 54 mm and thickness of up to 3 mm.

- Targets can be changed easily and quickly.

- The high target utilization saves costs.

- Sputtering of indium tin oxide (ITO) and carbon is possible. (Prerequisite: basic device CCU-010 HV)

- Detection and monitoring of implosion guard guarantees safe operation.

- Automatic target shutter.

- Electronically controlled process vacuum ensures stable pressure in the receptacle.

- Target cooling with temperature monitoring ensures smooth operation.

- Circular gas orifice ensures homogeneous process gas distribution.

- Uniform electrical and pneumatic interface for use with basic units CCU-010.

- No high voltage at electrical interfaces, because high-voltage supply is integrated into the head.

- Automatic process head recognition.

- Small size and weight.

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 100002 | SP-010 Sputter head | Each | p.o.r. |

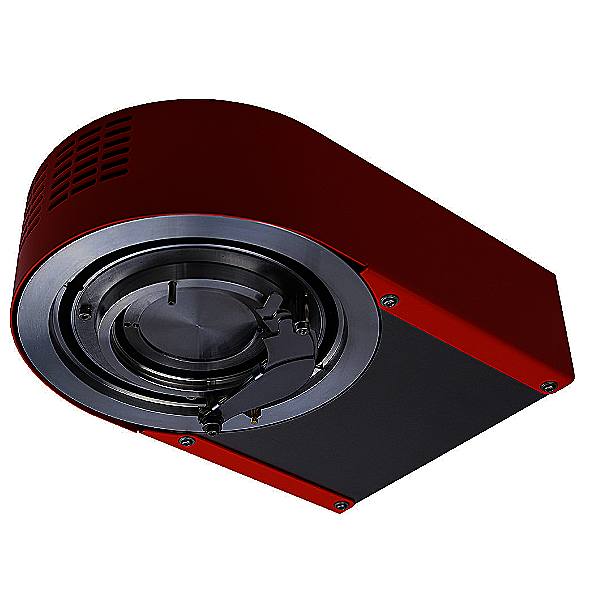

Description

An Intelligent Head

Adding the final touch!

Safematic sets new standards in laboratory coating with its compact sputter head.

Our SP-011 sputtering system is designed for high quality sputter deposition.

See for yourself the smaller form factor and the numerous features that our engineers have packed into this head.

The magnetron of the SP-011 sputter unit is designed for high power sputtering and for a broad range of coating materials.

Our sputtering modules plug into our CCU-010 HV and CCU-010 LV coating systems and are immediately ready to go.

Specifications

| Dimensions (L x W x H) | 230 x 160 x 60 mm |

| Weight | 2.9 kg |

| Targets | Ø 54 mm and thickness up to 3 mm |

| Connections, electrical | DSUB |

| Connections, gas | DSUB |

| Temperature range | 10 … 40 °C |

Features

- The magnetron sputter head allows high sputtering rates.

- For a extensive range of sputtering materials (Fe, ITO, C, etc.).

- Use of targets with a diameter of 54 mm and thickness of up to 3 mm.

- Targets can be changed easily and quickly.

- The high target utilization saves costs.

- Sputtering of indium tin oxide (ITO) and carbon is possible. (Prerequisite: basic device CCU-010 HV)

- Detection and monitoring of implosion guard guarantees safe operation.

- Automatic target shutter.

- Electronically controlled process vacuum ensures stable pressure in the receptacle.

- Target cooling with temperature monitoring ensures smooth operation.

- Circular gas orifice ensures homogeneous process gas distribution.

- Uniform electrical and pneumatic interface for use with basic units CCU-010.

- No high voltage at electrical interfaces, because high-voltage supply is integrated into the head.

- Automatic process head recognition.

- Small size and weight.

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 100012 | SP-011 Sputter head for high sputtering rates | Each | p.o.r. |

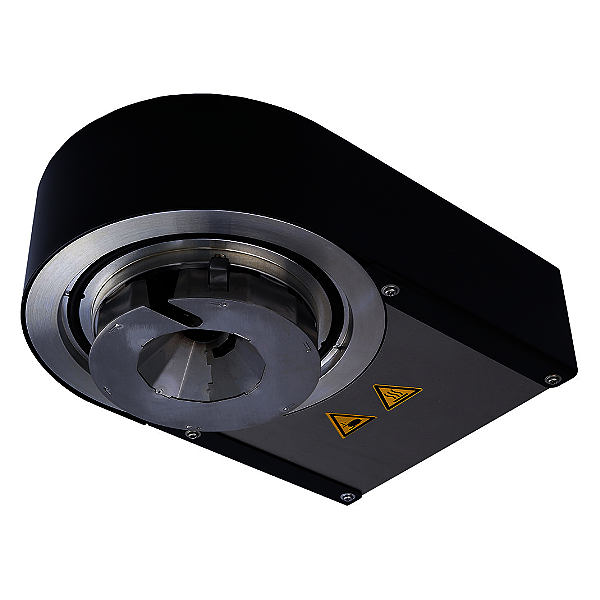

Description

An Intelligent Head

Safematic sets new standards in laboratory carbon coating with this compact carbon thread head.

The CT-010 uses a patented and unique carbon thread spooling system.

See for yourself the smaller form factor and the numerous features that our engineers have packed into this carbon thread head.

Specifications

| Dimensions (L x W x H) | 230 x 160 x 60 mm |

| Weight | 2.9 kg |

| Carbon thread | Carbon thread wound on coil |

| Connections, electrical | DSUB |

| Connections, gas | DSUB |

| Temperature range | 10 … 40 °C |

Features

- Patented unrolling for automatic thread transport in the vacuum.

- Automatic target shutter protects your samples during the degassing of the carbon thread.

- Electronically controlled process vacuum ensures stable pressure in the receptacle.

- Detection and monitoring of implosion guard guarantees safe operation.

- Plasma treatment of your sample is possible thanks to an optional plasma unit.

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 100003 | CT-010 Carbon thread head | Each | p.o.r. |

Description

Allows to Apply Plasma to the Substrates

For specimen pre-treatment or after-treatment combined with a coating process the etching unit allows to apply plasma to the substrates.

With this accessory one can select Argon, extra etching gas or environmental air either as process gas.

This allows cleaning of the samples prior to a coating and increasing the adhesion of thin films.

Additionally it would be possible to modify the surface properties of a coated sample by a plasma treatment after the coating.

With air plasma it is possible to turn a thin carbon layer from hydrophobic to hydrophilic for example.

The adjustable process pressure ranges from 2 E-1 mbar to 1 mbar with a selectable plasma current from 10 to 50 mA.

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 1000010 | ET-010 Option etching | Each | p.o.r. |

Description

Glow Discharge System

This is an option for the carbon thread head CT-010.

The optional GD-010 glow discharge system can quickly be installed for surface treatment by air, argon or by other dedicated gas plasma.

For example, it is possible to make carbon films hydrophilic.

This is greatly simplified because the carbon coating and glow discharge treatment can be done sequentially without the inconvenience of having to “break” vacuum conditions and exchange process heads.

This unit installed into CT-010 is compatible with all sample stages.

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 100004 | GD-010 Option glow discharge | Each | p.o.r. |

Accessories

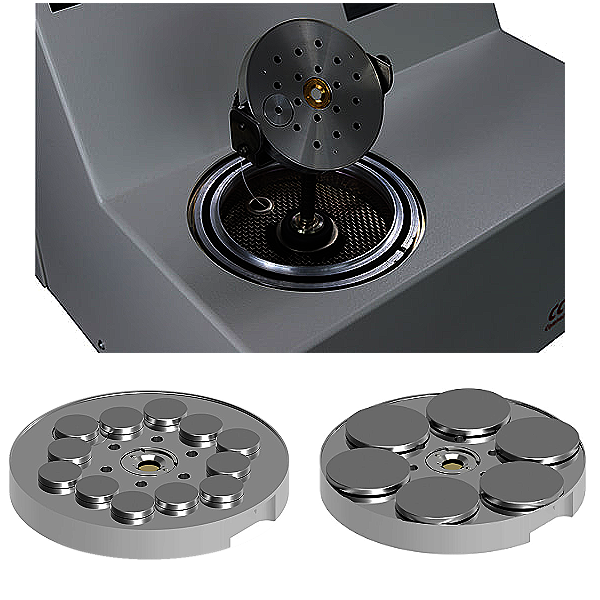

Description

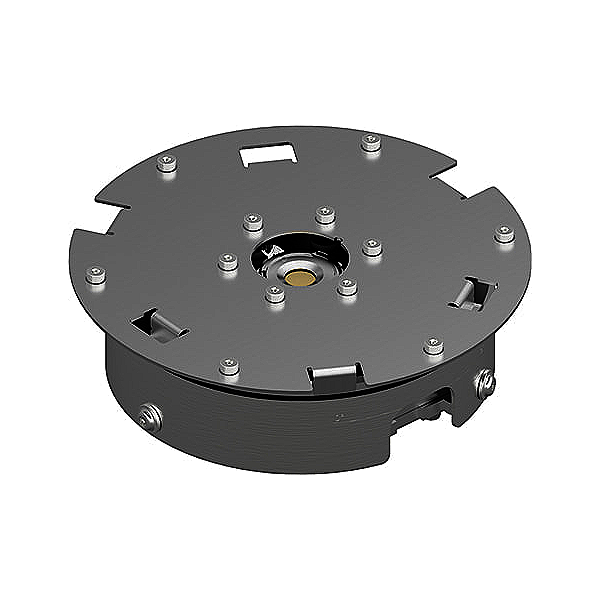

Standard Stage

The standard stage is connected to the tilt and height adjustable table of the CCU-010 of the basic unit.

It has a diameter of 80 mm and holds six large( 25.4 mm) or 18 small ( 12.7 mm) SEM pin stubs.

The table contains two slots for the quartz sensor (center position for normal use and edge position for larger samples).

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 400020 | Specimen stage with guide compl. | Each | € 1.315,00 |

Description

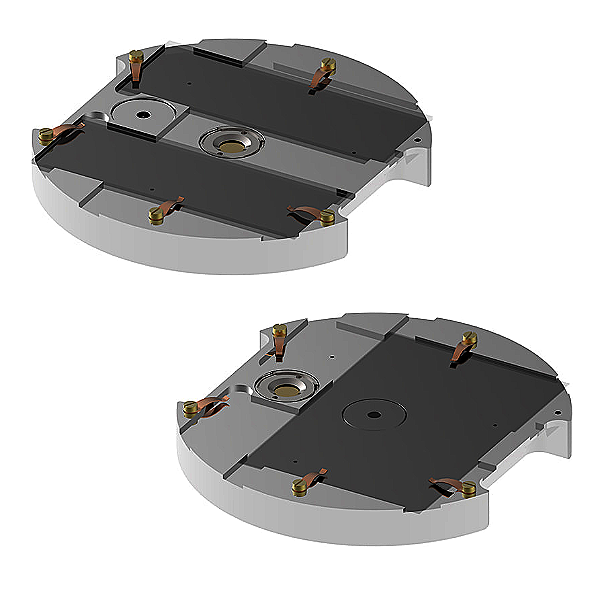

Specimen Stage for Microscopy Slides

The slides stage ST-010 carries two 26 x 76 mm (25 x 75 mm respectively) microscope slides or one 52 x 76mm (50 x 75 mm respectively) slide.

Due to the dual-position film thickness monitor, the quartz sensor is operational for both arrangements.

For fixation six S-clips are mounted with a small M2x3 screw which allows the S-clip to rotate.

The S-clips are made from conductive spring grade copper alloy.

Samples are clamped securely without the need for conductive adhesives or conductive pastes.

Sample changing is quick, easy and clean. Contamination issues due to adhesives or glues are eliminated.

Six mounting clips M2 are included.

The S-Clips are also separately available (Art. No. 1000119) to enable customers to make their own custom made sample clip holders.

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 1000088 | ST-010 Object slide table | Each | € 340,00 |

Description

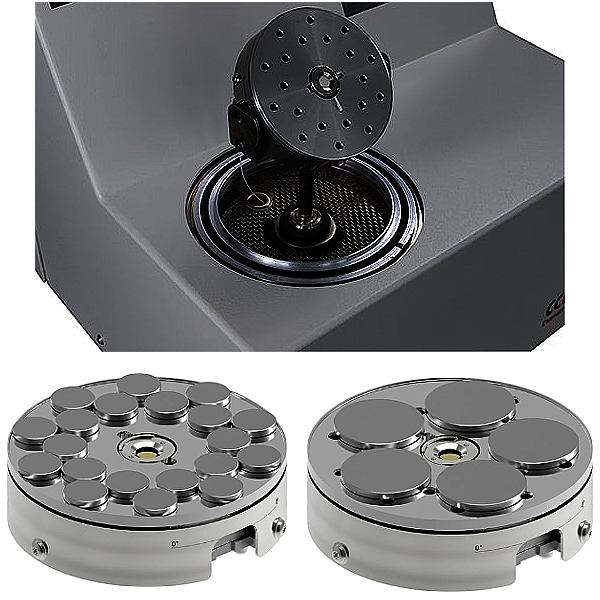

Rotary Table with Speed Regulation

The optional rotary table is attached to the existing stage of the basic unit.

An automatic table recognition and speed control (0 … 100 %) is already integrated into the software of the basic unit.

The table can hold a total of 20 sample stubs.

Simultaneous placement of 5 large stubs with a diameter of 25.4 mm or 10 small stubs with a diameter of 12.7 mm is possible.

|  |

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 100005 | RS-010 Rotary table | Each | € 2.660,00 |

Description

Planetary Gear Table with Speed Regulation

The optional planetary gear table is attached to the existing stage of the basic unit.

A film thickness monitor is fitted as standard which will precisely monitor and control film thickness of carbon and metal films.

An automatic table recognition and speed control (0 … 100%) function is integrated into the software of the basic unit.

The table can hold a total of 6 sample stubs.

The basic table turns clockwise, the 6 sample stub holders turn anticlockwise.

The optional rotary table is attached to the existing stage of the basic unit. An automatic table recognition and speed control (0 … 100 %) is already integrated into the software of the basic unit. The table can hold a total of 20 sample stubs. Simultaneous placement of 5 large stubs with a diameter of 25.4 mm or 10 small stubs with a diameter of 12.7 mm is possible.

|  |

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 1000130 | PS-006 Planetary gear table | Each | € 3.200,00 |

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 1000089 | PS-060 Rotary Support | Each | € 280,00 |

Description

Additional Specimen Etching Table

The etching stage is connected to the tilt and height adjustable table of the CCU-010 of the basic unit.

It has a diameter of 80 mm and holds six large ( 25.4 mm) or 18 small ( 12.7mm) SEM pin stubs.

The table contains two slots for the quartz sensor (center position for normal use and edge position for larger samples).

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 1000112 | Specimen stage ET-010 | Each | € 448,00 |

Description

Add the Etching Unit

You already have a low or high vacuum basic unit and would like to add the etching unit?

No problem!

The plasma treatment unit can be used in combination with the sputter head and/or the carbon thread head.

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 1000128 | ET-010R Retrofit Set | Each | € 4.230,00 |

Description

Vacuum Storage Box for CCU-010 Accessories

The new vacuum storage box allows you to keep the second coating head for your CCU-010 Compact Coating Unit and the full range of targets always clean and ready for use.

One additional glass tube and a second stage plate completely eliminate the problem of cross contamination between metal and carbon deposition.

This allows you to use one system for both metal and carbon coating.

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 1000087 | HS-010 Head storage box | Each | € 2.500,00 |

Description

Visualise Your Process!

The Windows software Coating LAB allows you to visualize process pressure, current, voltage, coating rate, coating thickness and sample temperature as real-time curves.

The integrated export function saves the values in an image format or as an Excel file, enabling you to process the data further.

Apart from the real-time curves, you can use the history function to import from the device and display the process details of the last ten coatings.

The coating unit is connected to the PC using the integrated USB interface.

Coating LAB establishes the connection to the device automatically.

Tools for configuring the system and updating the firmware have also been integrated. These are password-protected and only accessible to supervisors.

| System requirements HW | |

| Processor | 1 GHz |

| RAM | 512 MB |

| Memory 32 Bit | 850 MB |

| Memory 64 Bit | 2 GB |

| System requirements SW | |

| Client operating system | Windows 10, Windows 8.1, Windows 8, Windows 7 SP1, Windows Vista SP2 |

| Server operating system | Windows Server 2012 R2, Windows Server 2012 (64-Bit-Edition), Windows Server 2008 R2 SP1, Windows Server 2008 SP2 |

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 100008 | Coating LAB | Each | € 1.550,00 |

Description

CCU-010 Transport Case

This robust transport case enables the safe transport of the coating unit.

Wheels are included for easy handling.

It also has space for various accessories.

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 1000114 | Transport case for CCU-010 | Each | € 1.800,00 |

Description

Single-use Cylinder

Do you need a handy Argon bottle for quick use?

We can provide you with a single-use cylinder for dozens of runs.

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 1000117 | Argon (Ar) 5.0 single-use cylinder 50L | Each | € 66,00 |

Description

Pressure Reducer Micro

This pressure reducer is used with our single-use argon 5.0 cylinder.

It includes a 6 mm PE hose.

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 1000118 | Pressure Reducer Micro | Each | € 78,00 |

Description

Subsequent Retrofit

Do you want to convert your basic unit CCU-010 fine vacuum to a high vacuum device?

You can do that easily using the upgrade kit I.

The components of the upgrade kit are installed in the CCU-010 LV device.

To use it as a high vacuum device, you will still need your external backing pump.

| Turbo pump (Hi Pace 80) | |

| Speed 2 % | 90.000 min–1 |

| Final pressure according to PNEUROP | < 1 10–7 hPa | < 7.5 10–8 Torr | < 1 10–7 mbar |

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 200000 | HV Upgrade Kit I | Each | € 9.550,00 |

Description

Subsequent Retrofit? No Problem.

Do you want to convert your basic unit CCU-010 fine vacuum to a high vacuum device?

You can do that easily using the upgrade kit II.

The components of the upgrade kit are installed in the CCU-010 LV device.

To use it as a high vacuum device, you will not need any further components.

| Turbo pump (Hi Pace 80) | |

| Speed 2 % | 90.000 min–1 |

| Final pressure according to PNEUROP | < 1 10–7 hPa | < 7.5 10–8 Torr | < 1 10–7 mbar |

| Membrane pump (MD 1 VARIO-SP) | |

| Max. pumping speed | 1.8 m3/h |

| Speed range | 200 2400 min–1 |

| Final vacuum (abs.) | 1 / 0.75 mbar / torr |

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 200001 | HV Upgrade Kit II | Each | € 12.210,00 |

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 300015 | Carbon Thread on Coil | Each | € 79,20 |

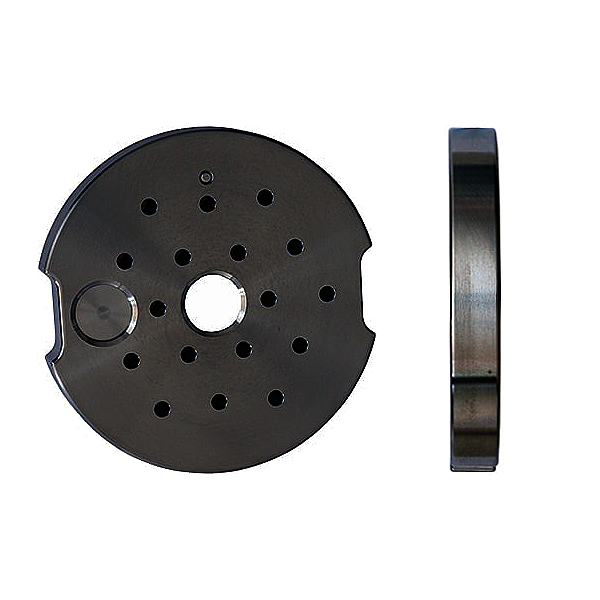

Description

Process Chamber

- Borosilicate glass 3.3

- glas chamber i.d. 104 mm, height 106 mm

- fire polished and flamed edges

- scale bar to indicate the working distance

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 400000 | Process Chamber | Each | € 232,00 |