Products

Cutlam 3.1

It’s the ultimate development of LAM PLAN and is the most advanced automatic Ø 300 mm cut-off machine in its market sector.

is the most advanced automatic Ø 300 mm cut-off machine in its market sector.

Largest cut-off area on the market of Ø 300 mm cut-off machines

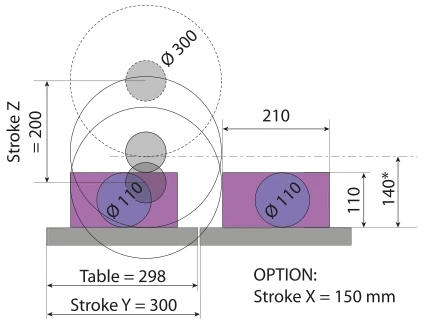

The CUTLAM®3.1 offers an unprecedented cutting capacity, the machine table can move forward and backward automatically over a distance of 300 mm.

New, the cut-off wheel has an automatic and linear top-to-bottom movement. With this linear movement, this new-generation of cutting machine offers a 140 mm space under the cutting wheel. The CUTLAM®3.1 has a cover which includes opening side to cut bars.

Many cutting possibilities are offered

This automatic cut-off machine makes it possible to cut vertically (along axis Z), over a maximum stroke of 200 mm, or to cut horizontally along axis Y, over a maximum stroke of 300 mm.

It is also possible to combine the two Z and Y movements. Thus, your machine will be able to perform cutting passes with a pass number and depth, which can be programmed.

This machine can optionally be equipped with a manual or automatic X axis for cutting parallel sections.

Easy to use

The CUTLAM®3.1 is extremely simple to operate with its large touch screen (5.7 inches) and intuitive interface. The 2 motorised axes of CUTLAM®3.1 (optional 3rd axis) can be controlled manually by two joysticks located near the control screen. The internal memory allow to save over 300 cutting programs, which can also be imported or exported via a USB port.

A great variety of possible setting configuration

The rotation speed of the cutting wheel and the feed speed of the axes can be programmed so as to prevent any deterioration or deformation of the samples. 3 cutting modes are possible: manual (via joysticks), semi-automatic and automatic. The movements of the axes can be continuous or sequenced.

The CUTLAM®3.1 is also equipped with the smart motion function: the definition of an acceptable torque for the cutting wheel, with the touch screen will automatically regulate the feed speed of the axes.

This option makes it possible to cut materials with different hardnesses (e.g. steel with an HVOF coating) without having to modify the feed speed. This option allows to avoid long testing campaigns to define the correct feed speed.

Theoretical cutting capacity

*space under wheel

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| B6305 | Cutting Machine CUTLAM 3.1 with Y and Z Axis Motorized | Each | p.o.r. |

Accessories

Description

Solid painted-steel piece of furniture specially designed for CUTLAM products.

It contains a storage door for tools and cut-off wheels, a drawer on top and a space for the recirculation tank.

This piece of furniture is stable and has adjustable feet.

For machine CUTLAM1.1

Dimensions L x H x P : 630 x 800 x 835 mm mm 60 M0100 00

For machine CUTLAM3.1

Dimensions L x H x P : 700 x 800 x 1050 mm

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 60 MO100 00 | CUTLAM support cabinet for Cutlam 1.1 | Each | p.o.r. | ||

| 60 M0310 00 | Support cabinet for CUTLAM 3.1 | Each | p.o.r. |

Description

The LAM PLAN vaccuming system extracts the “polluted” air inside the cutting chamber of your cutting machine.

- A special multilayer filter will stop the smallest polluting particles, thus preventing their dispersion into the atmosphere.

- The cutting fluid, in the liquid state, is returned to the cutting machine recirculation tank to be reused. (An evacuation is provided for this purpose on the vacuuming system).

- A cartridge post-filter, located above the suction system, ensures a high filtration level, up to 99.97%.

- An adapter part (LAM PLAN code 60CT20820) is provided to adapt the suction hose to the canopy of the LAM PLAN cutting machine.

- The vacuuming system is mounted on a trolley with wheels, allowing an easy positioning.

- A drain valve, located in the trolley, collects the condensate.

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 60 CT204 00 | Oil mist extraction device – A1 | Each | p.o.r. |

Description

Double vice with screw tightening system (left and right side of the wheel)

2 x 2 element vice, without sole to obtain maximal length clamping

Jaws width 80 mm, Jaws height 45 mm

T-slot 12 mm screw included

Left and right levers

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 60 CT200 40 | Double vice with screw tightening system | Each | p.o.r. |

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 60 081282 20 | Universal clamping KOPAL 61 | Each | p.o.r. |

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 60 081282 40 | Lift for KOPAL 61 | Each | p.o.r. |

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 60 00285 90 | Long cam for KOPAL 61 | Each | p.o.r. |

Description

Transversal table (X movement) manual movement with roller

stroke 150 mm,

Display accuracy: 0,01 mm

Can receive right vice reference 60 CT200 20 or 60 CT200 40

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 60 CT31A 20 | Transversal table (X movement) manual movement | Each | p.o.r. |

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 60 CT31A 30 | Automatic transversal table for Cutlam 3.1 | Each | p.o.r. |

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 60 CT306 20 | Specific vice with fast tightening system | Each | p.o.r. |

| Art. | Description | Unit | Price | Quantity | |

|---|---|---|---|---|---|

| 60 00373 90 | Adaptor rings 32 x 25,4 mm, steel | 5 | p.o.r. | ||

| 60 00374 90 | Adaptor rings 32 x 25,4 mm, PVC | 5 | p.o.r. |